August 19, 2024

The number of enterprises across globe in the manufacturing sector, projected to be 7.11 million in 2024, is expected to grow at a CAGR of 14.17% over next 5 years1. This significant increase implies tough competition and thus Profitability, Brand Value and Customer Satisfaction will become critical factors for any organization. Cost and quality of product will be important levers to ensure survival in a fierce, competitive environment.

According to a 2022 Forbes article, industrial manufacturers lose as much as 50 billion dollars per year2 to unplanned downtime. Furthermore, as a general rule quality-related costs for any organization can range between 10% to 15% of sales revenue3. Thus, controlling downtime and quality will decide the future of any organization.

TPM (Total Productive Maintenance) has proven its place in the industry for several decades, companies that embraced TPM have been able to control both downtime and cost.

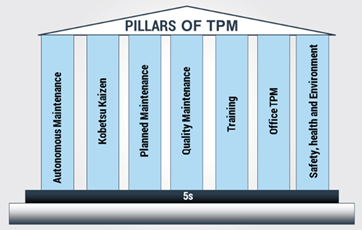

TPM philosophy, through its seven pillars, emphasizes on involving entire workforce in maintaining equipment and establishing proactive and preventive maintenance practices that lead to improvement in overall equipment performance and reliability.

How digital will help TPM Philosophy?

Fourth industrial revolution has brought digital shop-floor technologies such as OEE monitoring, real-time alerts and dashboards into the focus of entire manufacturing industry. Mature organizations are even exploring Artificial Intelligence and Machine Learning for manufacturing use cases.

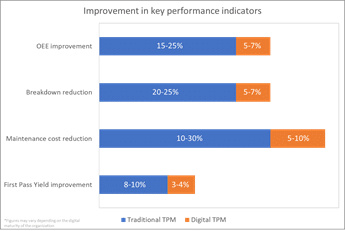

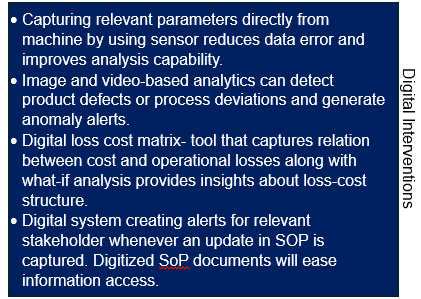

With digital becoming the norm in industry, fortifying TPM with digital technology will improve its success rate and boost returns. TPM 2.0, powered by Digital Tools, will improve maturity of maintenance practices and ease TPM adoption.

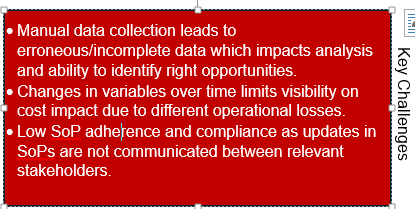

How can we redefine TPM pillars?

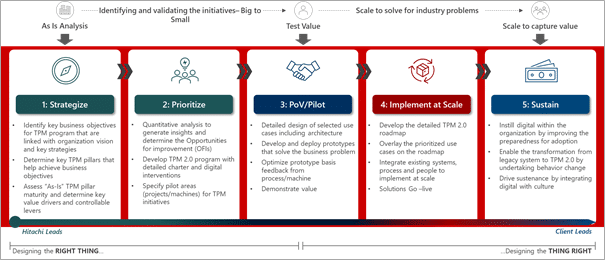

How should organizations adopt?

Digital adoption is already underway in many organizations as many digital use cases are getting developed and deployed. It is imperative to integrate this digital adoption with TPM philosophy to enhance returns from TPM initiatives.

Author: Hitachi Digital Services

Hitachi Digital Services, a wholly owned subsidiary of Hitachi Ltd., is an edge-to-core digital consultancy and technology services provider helping organizations realize the full potential of AI-driven digital transformation. Through a technology-unified operating model for cloud, data and IoT, Hitachi Digital Services’ end-to-end value creation for clients is established through innovation in digital engineering, implementation services, products, and solutions. Built on Hitachi Group’s more than 110 years of innovation across industries, Hitachi Digital Services helps to improve people’s lives today and build a sustainable society tomorrow. To learn more, visit https://www.hitachids.com