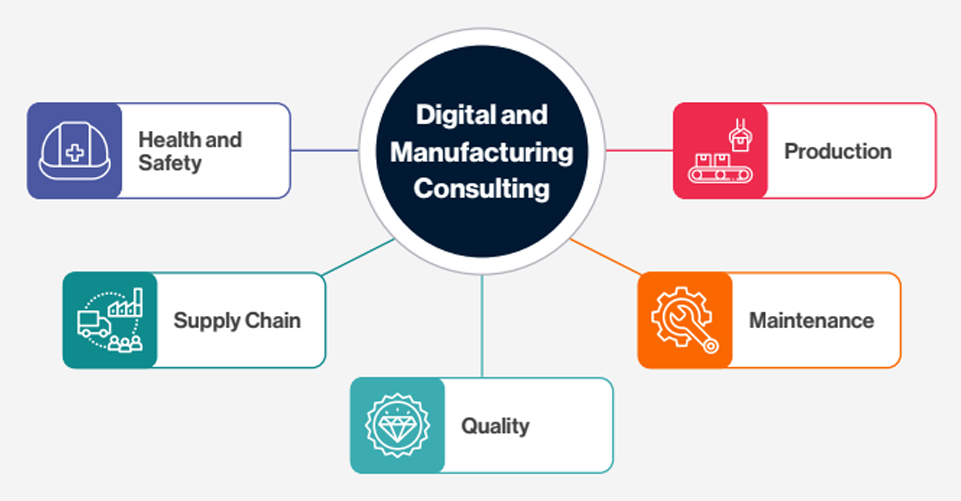

At Hitachi Digital Services, we bring together our learnings as a manufacturer with our domain expertise to enable outcomes that will accelerate your digital industrial transformation. We work with you to blend an approach that includes off-the-shelf solutions and specific, engineered solutions based on our solution cores, focusing on the production, quality, maintenance, supply chain, and health and safety domains.

Production

Our production solutions include tools for the real-time collection, processing and visualization of all relevant data on your shop floor, including machine learning (ML) tools for real-time process insights, end-to-end traceability, dynamic scheduling and much more.

Hitachi Digital Services production solutions enable process insights and optimization to maximize your throughput, boost your asset performance and efficiency, and help identify and eliminate shop-floor bottlenecks.

Maintenance

Leverage IoT and analytics for better equipment maintenance. Our maintenance solutions include equipment monitoring, KPI and trends analysis, anomaly detection, remaining useful life estimation, failure impact prediction, and predictive and prescriptive tools.

Balance the risk, cost, performance and reliability of your assets to maximize your predictable production at the lowest sustainable maintenance cost.

Quality

Transform process performance with an intelligent digital solution that gives you quality discrepancy detection, root-cause analysis and real-time notifications for production quality and traceability. Capabilities include descriptive qualitycontrol and predictive and prescriptive quality assurance.

Anticipate and manage your product quality issues to lower the costs of rework and reduce scrapped material, lost opportunity and lower line performance.

Supply Chain

Your manufacturing agility and supply chain responsiveness are key to meeting customer demand. You need greater visibility and predictability to optimize your supply chains and gain competitive advantage, stay agile, control costs and reduce working capital.

Real-time supply chain optimization uses data analysis to assess what-if scenarios to aid your tactical decision-making for actors across the supply chain, improving your customer service and inventory levels.

Health and Safety

Our digital health and safety solution for manufacturing combines strategic consulting with new digital technologies, such as 3D lidar, video, artificial intelligence (AI), radio-frequency identification (RFID) and data analytics, to reduce risk and optimize safety strategies, procedures and approaches.

Build an effective and holistic health and safety strategy for fewer injury claims, better employee retention, improved morale, reduced legal costs and brand protection.

Asset Insights

Asset performance is a key contributor to operational effectiveness, productivity and cost in manufacturing. Solutions for asset insights help you to balance the risk, cost, performance and reliability of your machinery, assets and infrastructure.

Enable critical work processes to safely maximize your predictable production at the lowest sustainable maintenance cost, while achieving quality targets within your business’s risk profile.